WELCOME

What's New

New

Model Houses New

Model Houses

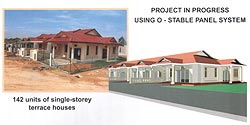

142 Units Single-Storey Terrace House

at P. J. Selangor Darul Ehsan has recently built for Perbadanan

Kemajuan Negeri Selangor. The buildings are situated not far from

Klang Valley city town, north ....... read more>>

0-Stable

Panel System (OSTAP System)

Pronounced “Zero-stable”, the O-Stable Panel System

is an enhancement on conventional prefabricated systems. Apart from

providing an elegant architectural finish, the main difference is

that the system uses

only single standard vertical and horizontal construction joints.

This prefabricated system allows attractive architectural styles

and features to be incorporated such as arches, round columns, cornices

and various kind of mouldings. The system can be adapted

to any design and any layout of the architect. The joints

of the components are strong, well-fitted, prevent water leakage

and hairline cracks.

In addition, hollow cores are formed in the vertical

pre-cast concrete panels, which provide the route for M

& E services and C & S requirements. The longitudinal

recesses at the edge form a core when two pre-cast wall panels are

placed in alignment and this provides a space of tolerance for easy

installation.

The houses built using this system are very cooling as the design

provides a series of strategically placed holes which allow for

cross and vertical

ventilation through the building. As a result, air-conditioning

may not be necessary for houses built under this system. An insulation

layer can be cast together inside all external wall panels, whenever

it is required by the client.

Under this system, concrete components for all columns, wall and

floor panels are cast in vertical and horizontal fiberglass moulds

with steel casings. All castings are done in a casting yard with

a light movable crane that does the lifting. The components are

removed from the moulds the day after casting and are ready for

use after four days. If necessary, the above column components can

be replaced by cast-in-situ concrete as required by frame structure

for high-rise buildings. At the building site, the components, which

satisfy existing fire requirements, are fitted into position by

the use of a light motorized crane.

The system reduces labour requirements by 50 percent and shortens

the building period. Using this system, a 500-unit housing project

can be completed in less than a year. Versatile

and economical,

the sys-tem can be employed to build just a single house.

With this system, there will be no

more need for artist’s impressions. Clients have the opportunity

to view their houses through the computer before casting and installation.

The client has the chance to highlight his views during the design

stage to avoid any modifications during construction. What you are

seeing on the computer is what your future house will look like

since every panel is cast by moulds.

With its classical colonial theme, the system provides a refreshing

change from normal run of the mill buildings.

Other architectural themes and designs will be introduced subsequently.

The system also allows for future expansion. Highly versatile, the

system can also be used to build bungalows, apartments and even

office buildings.

Apart from easy handling and speed, the system offers numerous advantages

during the construction process. As almost all wet on-site work

is eliminated, it maximises all-weather construction and facilitates

better quality control. With no scaffolding or props required, the

construction site is kept relatively clean and tidy.

The system also simplifies electrical, plumbing and rainwater down

pipe installation. The hollow core in the wall panels provides space

for all the service installations and future concealed wiring extensions.

The company claims that buildings constructed under the system offer

better resistance to hurricanes as the wall and floor panels, columns

and beams are tied together into a single unified box structure.

Developers who opt for this construction method will reap better

profit margins as the more elegant architectural design will attract

better response from purchasers and virtually eliminate complaints

of defects.

The turnkey contractor also benefits from the system as projects

will be completed faster, finished works are almost defect-free

and workmanship is of high quality. House buyers also reap the benefits

for high quality and architecturally attractive houses by paying

slightly extra.

The Company

In Malaysia, prefabricated building projects have often been associated

with drab low or medium-cost housing rather than the up-market sector.

However, a Malaysian-invented prefabricated building system now

allows luxurious homes with attractive architectural designs to

be constructed faster and with almost zero defect.

Launched in June 1999, the system was invented by our Technical

Advisor, an architectural engineer Khoo Tian after

extensive research over 10 years and an investment of some RM4

million. Khoo likens his system to that of Lego toys. The

company, O-Stable Panel Sdn Bhd, has secured patent rights from

the United States, New Zealand, the European Union and many other

countries and is also waiting for approval in Malaysia. Baktian

Sdn Bhd has been granted the exclusive license for this system in

Malaysia.

To prove that the O-Stable Panel System is not all hype, an experimental

project of 97 units of houses in Bidor, Perak is

being constructed using this method. The attractively designed houses

are priced from RM220, 000 to RM550, 000 inclusive

of RM70, 000 worth of luxurious finishing.

|