Performance under Vertical

Loads

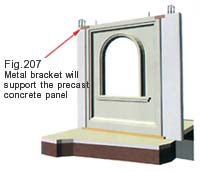

The precast wall panels are designed as load bearing wall system.

Depending on the height of the building, the thickness of the wall

panels can be varied. The wall is reinforced with BRC mesh at the

center both for the vertical load support as well as during the

lifting/installation stage. The wall is stiffened with enlargement

to 200mm thick at the edges and reinforced using high tensile reinforcement.

These top stiffened edges act as transfer beams for window or door

openings while the side stiffened edges allow stronger support during

lifting stage.

Integrity or Strength of Joints

The

thickening of the edge of the wall panel allows for a reasonable

size of vertical recess to be formed on either side of the wall

panel to form a core for the construction joint of 125 x 100 oval

shape cavity when two adjoining panels or panel and column are assembled

together and this provides a space of tolerance for easy installation.

This large cavity can be filled with chipping concrete well vibrated

to form a strong wet joint. This wet joint also acts as a cast-in-situ

stiffener (once a vertical steel bar has been inserted and concrete

has been poured into the core) and bonds the panel to the column.

As such, it can prevent the ingress of water effectively. This joint

is able to transfer lateral load by shear action of the concrete

infill to the adjacent columns. This can be further improved by

adding non-shrinkage cement-plaster to finish the construction joint

of all external walls. For horizontal construction joints, rawl

bolts are inserted into the floor beam for levelling control prior

to pouring the expandite concrete and installation of the precast

concrete wall panel. Two groove lines along the bottom face of the

panel will provide better bonding and also prevents ingress of water

effectively. The

thickening of the edge of the wall panel allows for a reasonable

size of vertical recess to be formed on either side of the wall

panel to form a core for the construction joint of 125 x 100 oval

shape cavity when two adjoining panels or panel and column are assembled

together and this provides a space of tolerance for easy installation.

This large cavity can be filled with chipping concrete well vibrated

to form a strong wet joint. This wet joint also acts as a cast-in-situ

stiffener (once a vertical steel bar has been inserted and concrete

has been poured into the core) and bonds the panel to the column.

As such, it can prevent the ingress of water effectively. This joint

is able to transfer lateral load by shear action of the concrete

infill to the adjacent columns. This can be further improved by

adding non-shrinkage cement-plaster to finish the construction joint

of all external walls. For horizontal construction joints, rawl

bolts are inserted into the floor beam for levelling control prior

to pouring the expandite concrete and installation of the precast

concrete wall panel. Two groove lines along the bottom face of the

panel will provide better bonding and also prevents ingress of water

effectively.

Performance under Lateral Loads

The lateral loads are transferred from the wall panels to the adjacent

columns via shear key action in the concrete infill between the

panel and column. These lateral loads are then resisted by the cast-in-situ

columns, which are adequately reinforced.

Durability and Design Life

As the system consists of cast-in-situ columns, precast concrete

wall panels and half-slab floor panels that are finished with in-situ

topping and BRC, the durability is essentially governed by performance

of concrete. With the Grade 35 concrete used, the panels are very

durable and the design life will exceed the 50 years required by

the code of practice.

Fire Safety and Toxicity

The grade 35 concrete precast panels provide very good fire resistance.

The concrete is non-combustible material and hence does not give

out any toxic gas

Environmentally Friendly

The construction site is practically free of messy clutter and debris

while being more environmentally friendly at the same time.

|